does an autoclave create a vacuum|high speed prevacuum sterilizer : purchaser How do you use an autoclave? Once the chamber is sealed, all the air is removed from it either by a simple vacuum pump (in a design called pre-vacuum ) or by pumping in . Each recommendation is categorized according to scientific evidence, theoretical rationale, applicability, and federal regulations. Examples are included in some .

{plog:ftitle_list}

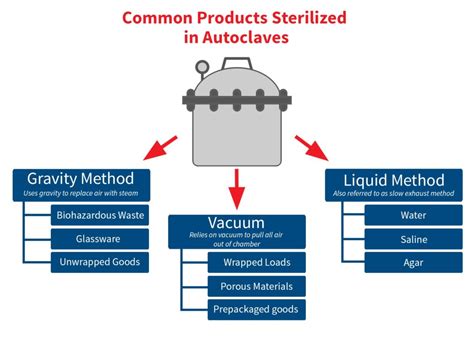

The basic principle of steam sterilization, as accomplished in an autoclave, is to expose each item to direct steam contact at the required temperature and pressure for the specified time. Thus, .

How do you use an autoclave? Once the chamber is sealed, all the air is removed from it either by a simple vacuum pump (in a design called pre-vacuum ) or by pumping in .Using pre-vacuum that utilizes a vacuum pump to remove the air from the vessel. [4] As air is removed, . Laboratory personnel should be trained before using the particular model of the autoclave. Do not overcrowd the autoclave and fill the . Vacuum autoclaves are designed to remove air and create a vacuum within the chamber before introducing steam. They are suitable for sterilizing materials that are sensitive to heat and moisture. 3. Ethylene Oxide . In healthcare, ensuring the sterility of medical instruments is crucial. Steam sterilization, or autoclaving, stands as a key defense against microbial contamination. Utilizing steam under pressure, this method .

The pre and post vacuum phase of the sterilization cycle; The autoclave jacket ; The cooling process; The autoclave control systems; . What does an autoclave do? An autoclave is used to sterilize surgical equipment, laboratory instruments, pharmaceutical items, and other materials. It can sterilize solids, liquids, hollows, and instruments of .The Importance of steam penetration: autoclave pressure and vacuum cycles (class B) . Fortunately, the self and remote diagnosis features of Celitron’s autoclaves make maintenance much less of a hassle. You can also rely on our reliable after-sales service. 3. Packaging matters because of autoclave pressure and steam Gravity displacement autoclaves use steam to displace the air in the chamber, while pre-vacuum autoclaves use a vacuum to remove the air before introducing steam. Both types of autoclaves are effective for sterilization, though pre-vacuum autoclaves are more efficient and may be preferred in some settings. Autoclaving Protocols An autoclave is a pressure chamber used to carry out industrial and scientific processes requiring elevated temperature and pressure different from ambient air pressure. The key function of an autoclave is to sterilize equipment and supplies by subjecting them to high-pressure saturated steam at 121°C (250°F) for around 15–20 minutes depending on the size of .

The gravity cycle is typically faster than the pre-vacuum cycle, as it does not require the removal of air from the autoclave chamber before sterilization. However, the pre-vacuum cycle is generally more effective at sterilization because it removes air from the chamber, which allows steam to penetrate materials more effectively. Common laboratory autoclave/table-top autoclave - This type of autoclave has a capacity of between 20 and 80 liters and is one of the most common autoclaves in laboratories. The majority of modern table-top autoclaves are automated and consist of a vacuum pump. The two basic types of steam sterilizers (autoclaves) are the gravity displacement autoclave and the high-speed prevacuum sterilizer. In the former, steam is admitted at the top or the sides of the sterilizing chamber and, because the steam is lighter than air, forces air out the bottom of the chamber through the drain vent.A vacuum pump sucks air or air/steam mixtures from the chamber. Superatmospheric cycles: Achieved with a vacuum pump. It starts with a vacuum followed by a steam pulse followed by a vacuum followed by a steam pulse. . If the autoclave does not reach the right temperature, the spores will germinate when incubated and their metabolism will .

reinforcement into a mould, vacuum bag the mould and laminate and then cure it in an autoclave or an oven. Although autoclaves are beyond the budget of individuals and most small businesses, curing prepregs in an oven, known as ‘out-of-autoclave’ or ‘oven-only’ curing, is . Be Precautious while using Autoclaves. Do not sterilize waterproof or water-resistant materials like oil or powders. Do not overcrowd the autoclave with the vessel and equipment. If possible sterilize your equipment in a shift-wise manner. Only use autoclavable bags to autoclave packages wastes. Use autoclavable bags to sterilize your equipment.

The air must be removed from the chamber either by a vacuum process (as in large autoclaves that use a pump or an ejector) or by a displacement process (as in some smaller tabletop autoclaves). Now that the air is removed, we increase the temperature and pressure by closing the chamber exhaust valve while continuing to add steam to the chamber . 2. How does a class S autoclave work? This category of mid-tier autoclave uses a wall of steam denser than air and repeats the process three times to make sure all the air within the machine’s chamber is extracted. . An autoclave that allows for “pre-vac” cycles can help with this. An autoclave with a vacuum pump allows you to draw a partial vacuum in the chamber during the initial heating period when the chamber fills with steam. .The 'B' type autoclave, also known as a vacuum autoclave, uses a vacuum pump to remove air from the chamber to allow steam to effectively penetrate the load. This continues until the appropriate pressure and temperature is achieved to sterilise the items. Once sterilisation is complete, the exhaust valve opens to release the steam and reduce .

The method used in Autoclave to remove the germs and make equipment microbes free uses pressure and moist heat. The method of working and the design of the Autoclave refers to the pressure cooker. Moreover, the Autoclave is also known as a pressure sterilizer. . This type of Autoclave consists of a vacuum pump and steam generator. . Direct-Steam heated autoclaves generally work by exposing the product to heat that is approximately 270° F (132° C). As the autoclave fills with steam the air is removed from the main chamber to create a vacuum seal. This process is typically completed using a vacuum pump or by forcing the air out through the use of steam. Celitron’s autoclaves make this whole process easier with a fully automated operation and precise temperature controls ranging between 121 and 134 degrees Celsius. . Vacuum autoclaves can remove all the air from the steam sterilizer’s chamber, thereby removing one of the most important obstacles of sterilization, and ensuring much more .

‘Autoclave’ is a term used mainly in laboratories whilst ‘Sterilizer’ is used more commonly for medical and pharmaceutical applications. Skip to main content +44 (0)20 8309 2031. Home; Products; . By far the most effective way of air removal is a vacuum system, whereby a vacuum is achieved in the chamber before any introduction of . Pre-vacuum Autoclaves: Pre-vacuum autoclaves, also known as vacuum autoclaves, employ a vacuum pump to remove air from the chamber before introducing steam. The removal of air enhances steam penetration and allows for more efficient sterilization. Pre-vacuum autoclaves are ideal for sterilizing heat- and moisture-sensitive materials. In some types of autoclaves, a separate vacuum generator is present which pulls out the air from the inside of the chamber to create a vacuum inside the chamber. The presence of some air pockets inside the chamber might support the growth of different microorganisms. This is why the vacuum chamber is an important component of an autoclave.

Vacuum Pump (optional): In some autoclaves, a vacuum pump is used to remove air from the chamber, ensuring efficient steam penetration. By understanding these components and their functions, you can better operate and maintain an autoclave for effective sterilization. Autoclave Temperature How does an autoclave kill microorganisms? Discover the intricate process behind this powerful sterilization method that ensures safety. Call Us: (02) 8880 7813. . Many autoclaves use a vacuum pump to improve steam penetration by removing air pockets from the chamber and materials. This allows the steam to contact all surfaces directly . In most vacuum autoclaves, the vacuum function is applied first to remove the air in the chamber and then steam is added until the target temperature and pressure is achieved to start the cycle. In gravity autoclaves or gravity displacement / downward displacement autoclaves, the pressurized steam does the work of pushing out and replacing the . Autoclaves function in three main phases: Conditioning: In the conditioning phase, the autoclave removes air from the chamber with a vacuum process or by flushing steam with movement supplied by pressure pulses. Gravity-style sterilizers displace the chamber’s air with steam, pushing the air out of the drain.

how does a honey refractometer work

vacuum vs non vacuum autoclave

vacuum vs non autoclave

steam sterilizer vs autoclave

en résumé, les bois ne sont pas bien séchés avant usinage et traitement d'où le grande nombre de clin tordu chez le gsb. Je suis sceptique sur la tenue en bardage (pas la .

does an autoclave create a vacuum|high speed prevacuum sterilizer